Scale Clean: A groundbreaking solution for preventing pipe scale buildup

Pneumatic Co., Ltd.

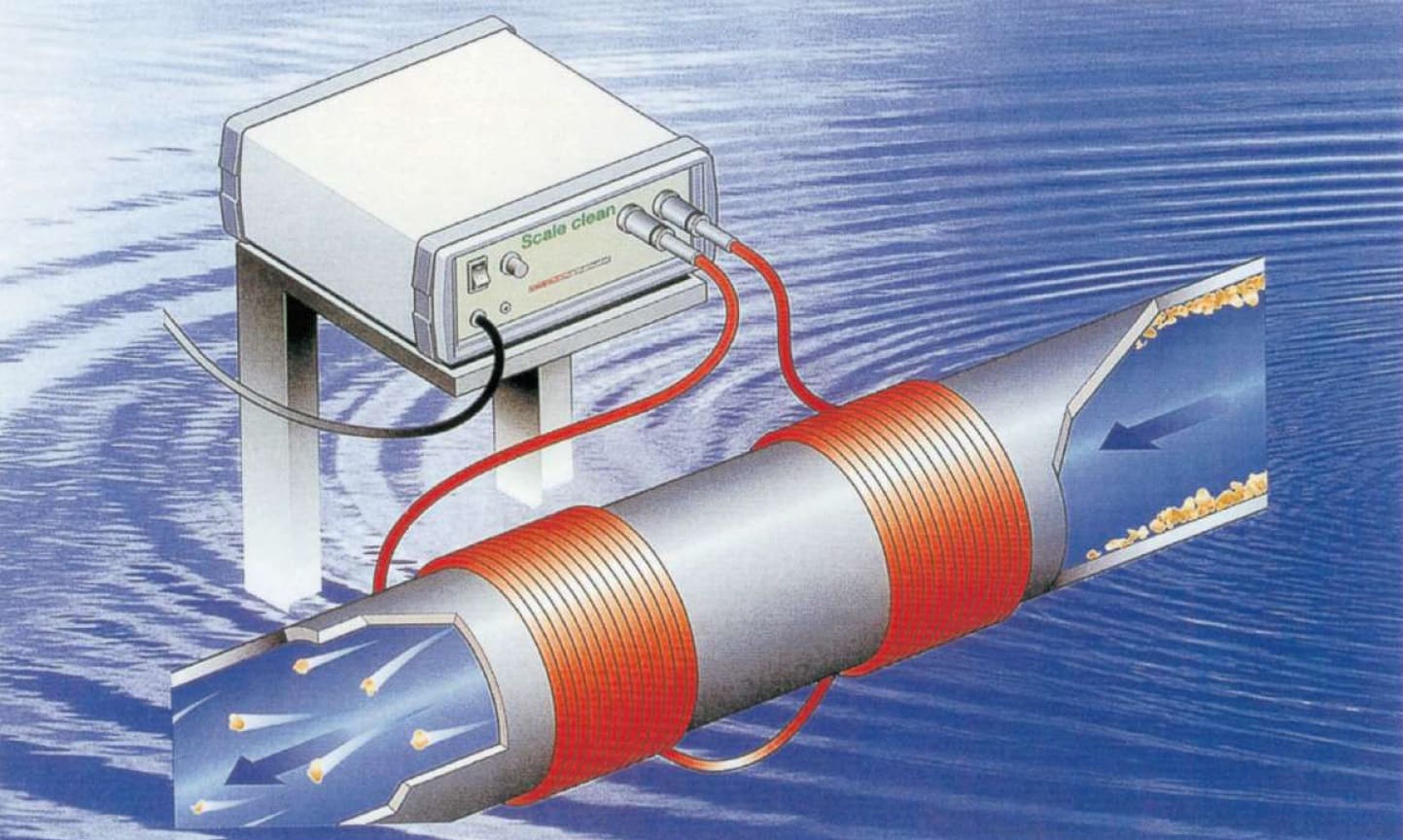

Graphic of the main unit

Are you struggling with high costs from chemical treatments or frequent cleaning to control scale buildup?

Scale buildup in heat exchangers and cooling tower piping can drastically reduce heat transfer efficiency. If left untreated, it may lead to serious disruptions such as production line shutdowns.

Traditionally, countermeasures have involved periodic chemical dosing or halting operations for cleaning—both costly and environmentally harmful.

Our Scale Clean system offers a reliable solution to these issues.

It is easy to install and operates with minimal running costs—around 200W. Its simple and durable design has earned high praise from our customers.

Why not rethink your scale control strategy with Scale Clean?

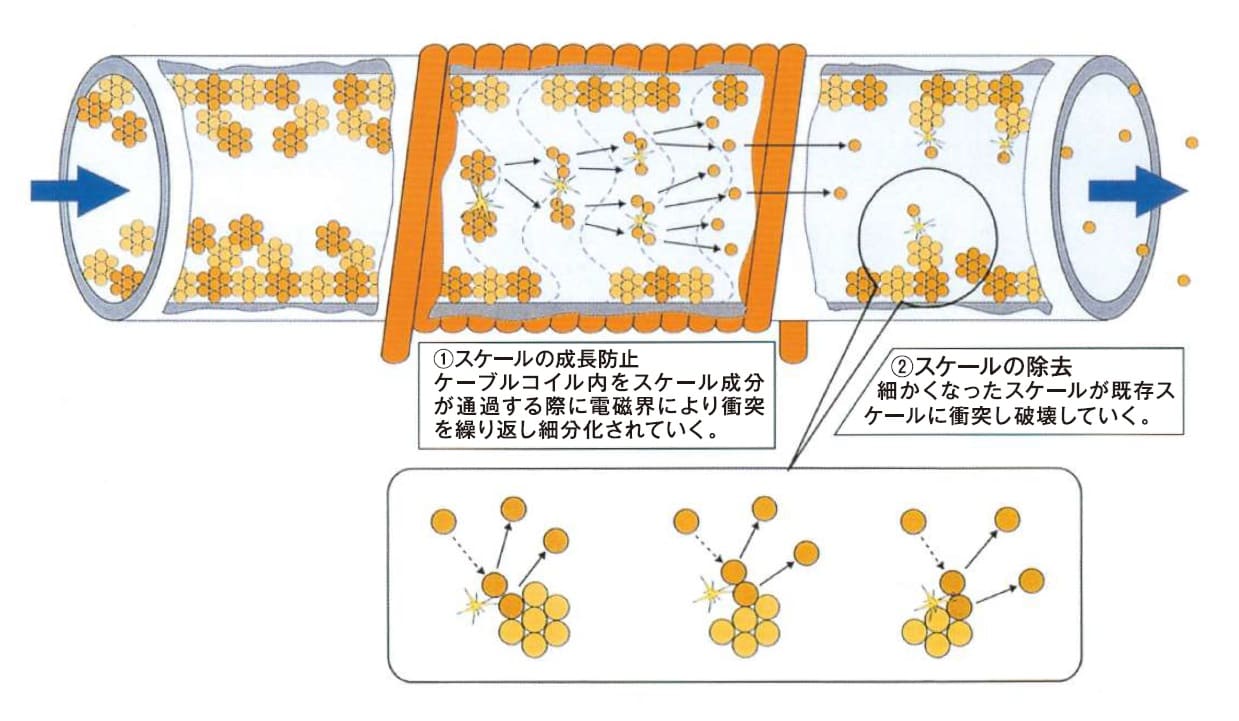

How it works

Major reductions in running cost

Scale Clean is an electromagnetic water treatment system.

It works by sending electromagnetic waves of varying wavelengths through coils installed on the surface of the piping. This induces repeated collisions among scale-forming particles, breaking them down into finer particles. As a result, the formation of scale from substances such as silica, calcium carbonate, and magnesium hydroxide is significantly reduced.

The system operates with an average power consumption of less than 200W, keeping running costs low and requiring no special power infrastructure.

With no moving parts such as motors, fans, or pumps—there are no consumable components that need replacement. In fact, many customers report uninterrupted operation for over 20 years without a single failure.

Some users have reduced annual chemical costs by as much as 5 million yen, while others have eliminated the need for biannual production line shutdowns for scale removal—resulting in substantial reductions in maintenance and operating costs.

It works by sending electromagnetic waves of varying wavelengths through coils installed on the surface of the piping. This induces repeated collisions among scale-forming particles, breaking them down into finer particles. As a result, the formation of scale from substances such as silica, calcium carbonate, and magnesium hydroxide is significantly reduced.

The system operates with an average power consumption of less than 200W, keeping running costs low and requiring no special power infrastructure.

With no moving parts such as motors, fans, or pumps—there are no consumable components that need replacement. In fact, many customers report uninterrupted operation for over 20 years without a single failure.

Some users have reduced annual chemical costs by as much as 5 million yen, while others have eliminated the need for biannual production line shutdowns for scale removal—resulting in substantial reductions in maintenance and operating costs.

Installation examples

Easily installs on existing piping systems

Installation is very simple. Because the existing piping does not need to be disassembled, there is no need to shut down the production line. Wrap the coils around the outside of the existing piping, connect the coils to the controller, and connect the controller to the main power supply; installation is complete.

The system can be fitted to pipes made of various materials, including carbon steel, stainless steel, and PVC.

The system can be fitted to pipes made of various materials, including carbon steel, stainless steel, and PVC.

Seismic Engineering Services

An extensive track record of installations

We have delivered over 500 units not only in Japan, but also across South Korea, China, Taiwan, Malaysia, Indonesia, Thailand, and other regions.

Our system has been successfully adopted in a wide range of facilities for various applications, including:

•Prevention of scale buildup in industrial water and chemically mixed water

•Prevention of scale in water circulation systems, such as heat exchangers and molds

•Elimination and prevention of rusty water in boiler feedwater and cooling towers

•Prevention of scale deposits in hot spring piping systems

•Elimination and prevention of rust, limescale, and biofilm (slime) in water systems

•Prevention of scale accumulation in wastewater recovery lines

•Prevention of scale in exhaust gas treatment scrubbers

Our system has been successfully adopted in a wide range of facilities for various applications, including:

•Prevention of scale buildup in industrial water and chemically mixed water

•Prevention of scale in water circulation systems, such as heat exchangers and molds

•Elimination and prevention of rusty water in boiler feedwater and cooling towers

•Prevention of scale deposits in hot spring piping systems

•Elimination and prevention of rust, limescale, and biofilm (slime) in water systems

•Prevention of scale accumulation in wastewater recovery lines

•Prevention of scale in exhaust gas treatment scrubbers

- URL (Japanese):https://www.jsj.co.jp/