Non-contact Safety Door Switches with High Durability and Superior Safety Performance

Examples of installation and usage of non-contact safety door switches

Easy to mount and adjust, our non-contact interlock safety door switches are highly dustproof and waterproof (IP68/IP69K).

Our non-contact safety door switches detect the opening and closing of safety covers, doors, gates, and fences. With a non-contact system that eliminates the risk of mechanical wear and failure, they boast extremely high durability. Compared to mechanical switches, the positioning of the receiver and transmitter units is easier to adjust, simplifying installation and maintenance. These door sensors are designed with safety as the highest priority.

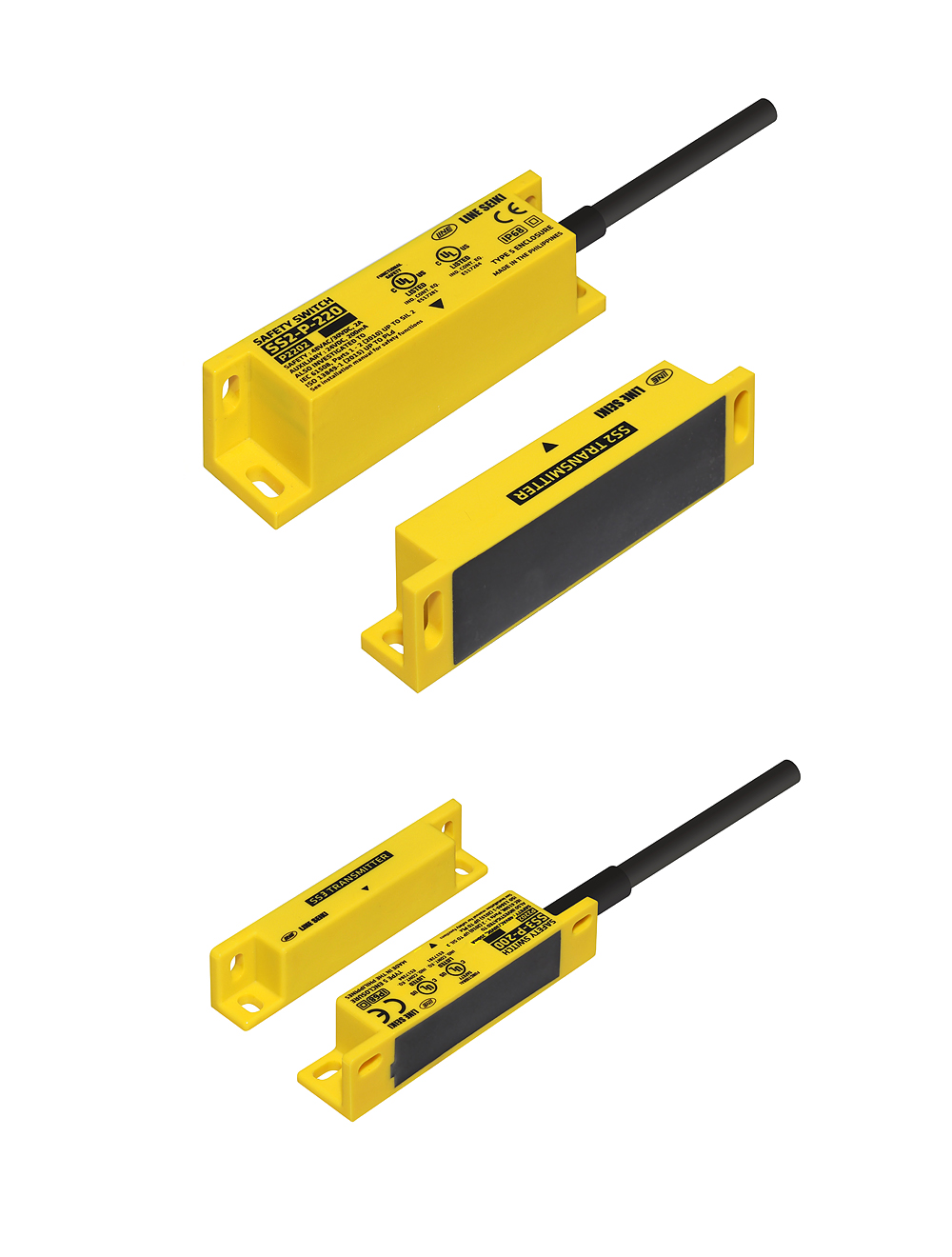

SS2 and SS3 series (plastic type)

Non-contact safety door switches SS2 and SS3 (plastic type)

- High Reliability

The internal architecture is designed to ensure safety even in the unlikely event of an emergency.

- High Durability

Non-contact safety door switches are free from the mechanical wear or failure that occurs with mechanical switches.

- Excellent Dust and Waterproof Performance

We achieved an IP68 rating by sealing the housing. Suitable for use in harsh environments.

- Stand-Alone Application

The built-in anomaly detection circuit for the SS2 series reduces costs by eliminating the need for a relay unit.

- Easy Mounting and Adjustment

The non-contact system makes it easier to mount the switch and adjust the positioning.

- Invalidation Prevention

Coding is achieved by using multiple magnets, which prevents the invalidation of safety functions.

SS2 and SS3 series (stainless type)

Non-contact safety door switches SS2 and SS3 (stainless type)

- Laser Printed Housing

The surface of the stainless steel housing is laser printed, preventing contamination by foreign materials from the safety switch itself.

- Excellent Dust and Waterproof Performance

We achieved an IP69K rating for the stainless type by sealing the housings, making it suitable for use in harsh environments.

Creating products that benefit society and are gentle to people

A global sales network and robust quality control

Currently, our products are used by more than 20 equipment and machinery manufacturers in Japan, such as semiconductor manufacturing equipment, food and meat processing machinery, foreign object inspection devices, and packaging machinery.

Ensuring Precise Positioning in Semiconductor Material Handling

Use Case 1: Semiconductor material handling system

The SS2 series features anti-bypass coding, a built-in protective fuse, and fault detection to help maintain safety compliance.

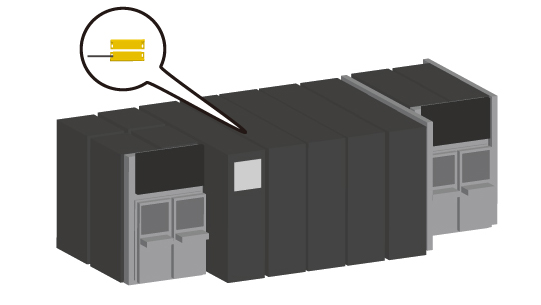

Protecting Operators by Preventing Unsafe Machine Operation

Use Case 2: Food-processing equipment doors

Safety interlock switches detect guard status so the machine immediately stops when the guard is open and runs only when it is closed.

The SS2 series adds anti-bypass coding, a built-in protective fuse, and fault detection to help ensure reliable protection.

- URL (English):https://www.lineseiki.com/

- URL (Japanese):https://www.line.co.jp/