Cutting Nozzles: Precision Filling Without Drips

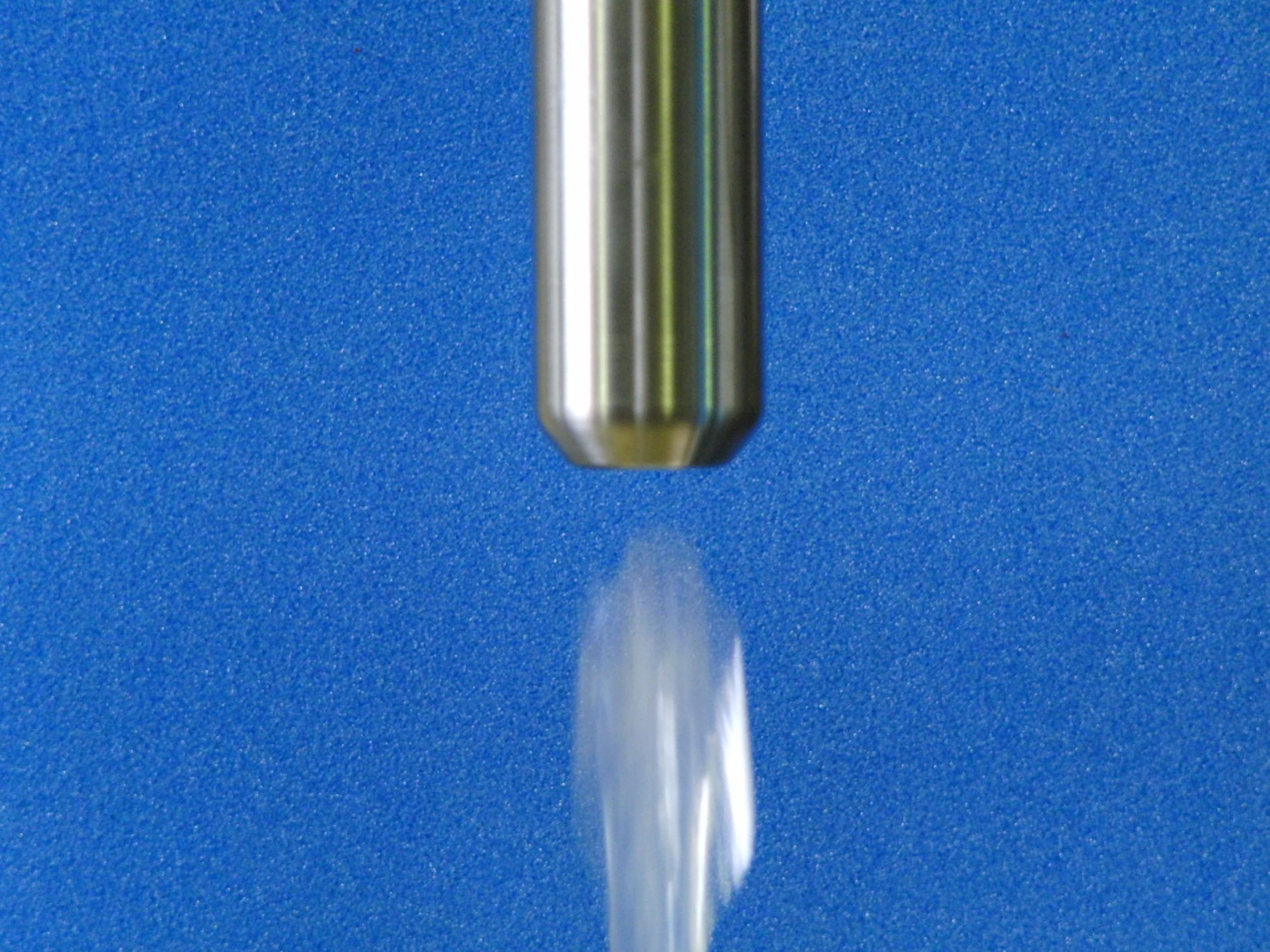

Cutting nozzle

Eliminating waste in production

Cutting nozzles are precision components for automated filling machines, ideal for high-viscosity liquids such as chocolate, lotion, and adhesives. They cleanly cut off the flow without leaving strings or drips.

There’s no need to wait for drips to subside or remove residual strings manually. The clean separation prevents defects, reduces the need for inspections and cleaning, and significantly lowers overall production costs.

Reducing waste also contributes to environmental sustainability. Simply replacing the nozzle can improve production capacity, reduce defect rates, and shorten work hours—resulting in planned, eco-friendly manufacturing.

This performance has been recognized and adopted by numerous companies across industries.

The moment of liquid cut-off

No-dripping filling nozzles

But the benefits do not stop there. That single issue of stringing triggers a cascade of hidden costs:

• Scrap from discarded product

• Increased labor hours for cleaning

• Opportunity losses from overproduction used as a safety margin

• Ultimately, higher total costs

Our cutting nozzles are designed to eliminate these invisible costs and stresses. This is more than a simple parts replacement; it is a solution that restores manufacturing quality and efficiency, giving your team back valuable time and resources.

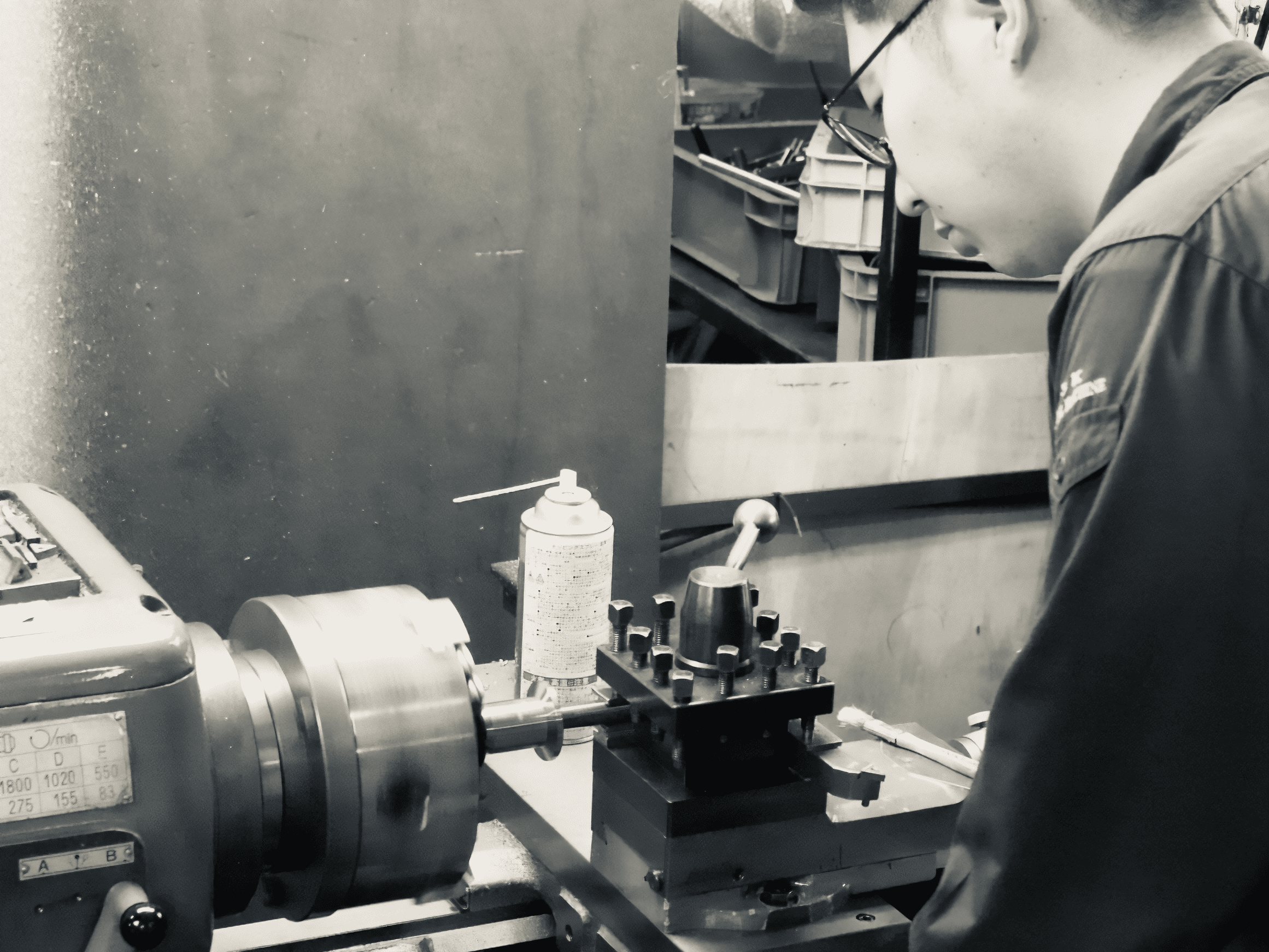

Fabricated by craftsmen

Long-lasting, repairable filling nozzles

Even if the liquid cut-off performance deteriorates over extended use, the nozzle can be recalibrated or adjusted to match its current condition. This ensures a long-lasting and cost-effective operation over time.

Image illustrating cost reduction

Reducing defective products to 1/100

Lower defect rates not only lead to a higher yield of quality products, but also prevent the accumulation of hidden costs such as disposal of defective items, raw materials and labor for surplus production, inspection efforts, and cleaning work. These savings translate into significant cost advantages.

This is one of the key reasons why our cutting nozzles are trusted by many OEM manufacturers.

-

- URL (Japanese):https://www.akimotosanki.co.jp/